[Case study] Design of a case packer and palletizer for packaging doypacks

Context

In order to increase its production capacity, our client was considering the creation of a new Doypack production line. For its end of packaging line, it called on MG Tech to design a case packing machine and a robotic palletizing solution. It was looking for a compact solution that could be easily installed in its existing workshop.

Product technical specifications:

- Two Doypack product formats, 200g and 250g

- Two case formats + lid

- Edge-mounted packaging of 6 or 12 products

Production rates:

- Maximum product rate: 90 products/min

- Maximum case rate: 15 cases/min

Solution proposed and supplied by MG Tech

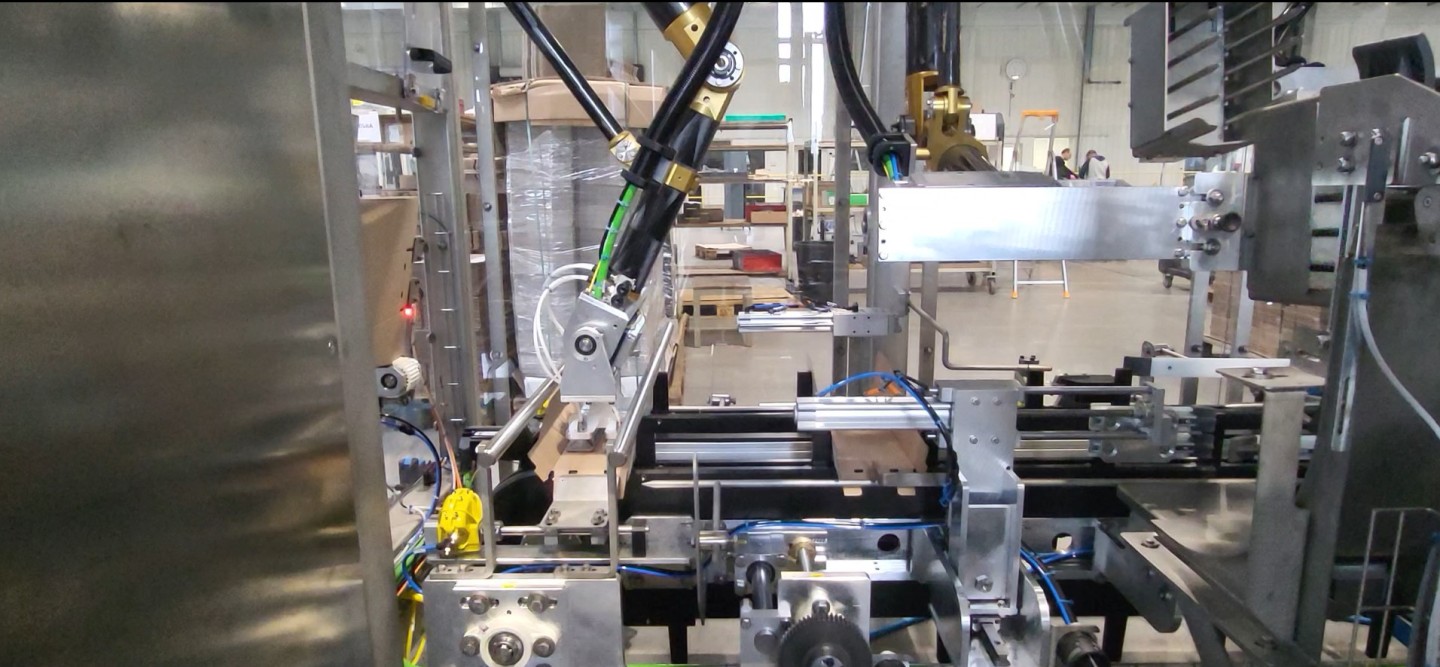

We designed a complete end-of-line packaging system, from product packing into cartons to palletizing, to ensure the packaging of Doypacks in cardboard boxes.

First, the products are picked by two multi-articulated robots equipped with a claw gripper to transfer batches of 6 or 12 products edge-mounted into a display case. A lid is then applied, and the case is inspected for several technical aspects: proper closure of the case and the correct number of products in the case. This type of packaging allows the client to optimize product transport. It also saves time during shelf placement in supermarkets because the display carton is placed directly on the shelves, as is, with only the top lid removed.

Subsequently, a robotic palletizer grips rows of cases with grippers and assembles the pallets according to the required drawings. Interlayers are inserted between the layers as needed.

Advantages of the solution:

The proposed solution offers the client a complete end-of-line packaging solution, addressing several key challenges:

- A compact solution, perfectly suited to space constraints, allowing the integration of a new line into a factory already equipped with two production lines.

- Direct product loading, limiting intermediate transfers, guaranteeing both time savings and optimal product placement in the cases.

- Simplified format changeover, designed to facilitate operator work and reduce downtime during transitions between batches.

Why did the client choose MG Tech?

The client's choice of MG Tech is based on a relationship of trust established over the course of several projects. The client owns several MG Tech machines and is satisfied with the use, efficiency, and reliability of their equipment. This positive experience with our solutions naturally reinforced their desire to continue working with us.

Another determining factor in this choice is the multidisciplinary nature of our teams. MG Tech offers a comprehensive approach to the end of the packaging line, allowing the client to benefit from a comprehensive offering while having a single point of contact to manage the entire project. This organization considerably simplifies communication, coordination, and technical monitoring, while ensuring perfect consistency between the various solutions implemented.