-

What challenges do dairy product manufacturers face in packaging?

Dairy manufacturers face several specific challenges at the end of the packaging line, relating to quality, safety, sustainability, and operational efficiency.

1. OPTIMIZING PRODUCTION RATES AND REDUCING COSTS

- Automation: Using robots for sorting, palletizing, and quality control, increasing throughput and reducing human error.

- Line flexibility: Adapting to different packaging formats (bottles, pots, cartons, trays) and market developments (individual portions, large packs).

- Loss minimization: Optimizing machine settings to reduce raw material and packaging waste.

2. SAFETY AND REGULATORY COMPLIANCE

- Product traceability: Implementing barcodes, QR codes, or RFID to ensure accurate batch tracking and respond quickly in the event of a product recall.

- Enhanced quality controls: Automatic verification of weights, labeling, and sealing to avoid regulatory non-compliance.

3. SUSTAINABILITY AND REDUCED ENVIRONMENTAL IMPACT

- Eco-design of packaging: Elimination of unnecessary plastics, adoption of recyclable or compostable packaging (e.g., yogurt cartons, recycled PET bottles).

- Transportation optimization: Reducing packaging weight and improving storage to limit logistics costs and carbon footprint.

Dairy manufacturers must therefore reconcile industrial efficiency, compliance with standards, product quality, and environmental commitment, while meeting consumer expectations for convenience and transparency. Innovation in packaging and automation is a key lever for meeting these challenges.

-

A range of packaging machines perfectly suited to dairy products

We manufacture several types of machines to support your end-of-line packaging operations. We offer a wide range of machines for overwrapping and sleeve/stapler application, case erectors, top-load or wrap case packers, and palletizers.

To reduce your space requirements, we can also design "combined" systems, solutions that combine different functionalities into a single machine.

Our expertise in the dairy sector allows us to provide customized solutions that meet the specific requirements of each product, such as texture or packaging format. We design and manufacture packaging machines for the dairy industry to optimize production and ensure packaging safety throughout the product transfer.

Automated cardboard forming

Our case erectors are designed to meet your space and throughput constraints. We offer several ranges of case erectors to ensure your dairy products are optimally packaged for safe transport. In addition, cardboard consumption is optimized and waste is reduced with a high-performance case erector.

Wrapping machines

Product wrapping allows the grouping of several products, particularly used in the dairy industry for a neat presentation to the consumer. This wrapping solution is ideal for injected or thermoformed cups, ensuring optimal protection and a neat presentation of your yogurts, dairy desserts, and other fresh products.

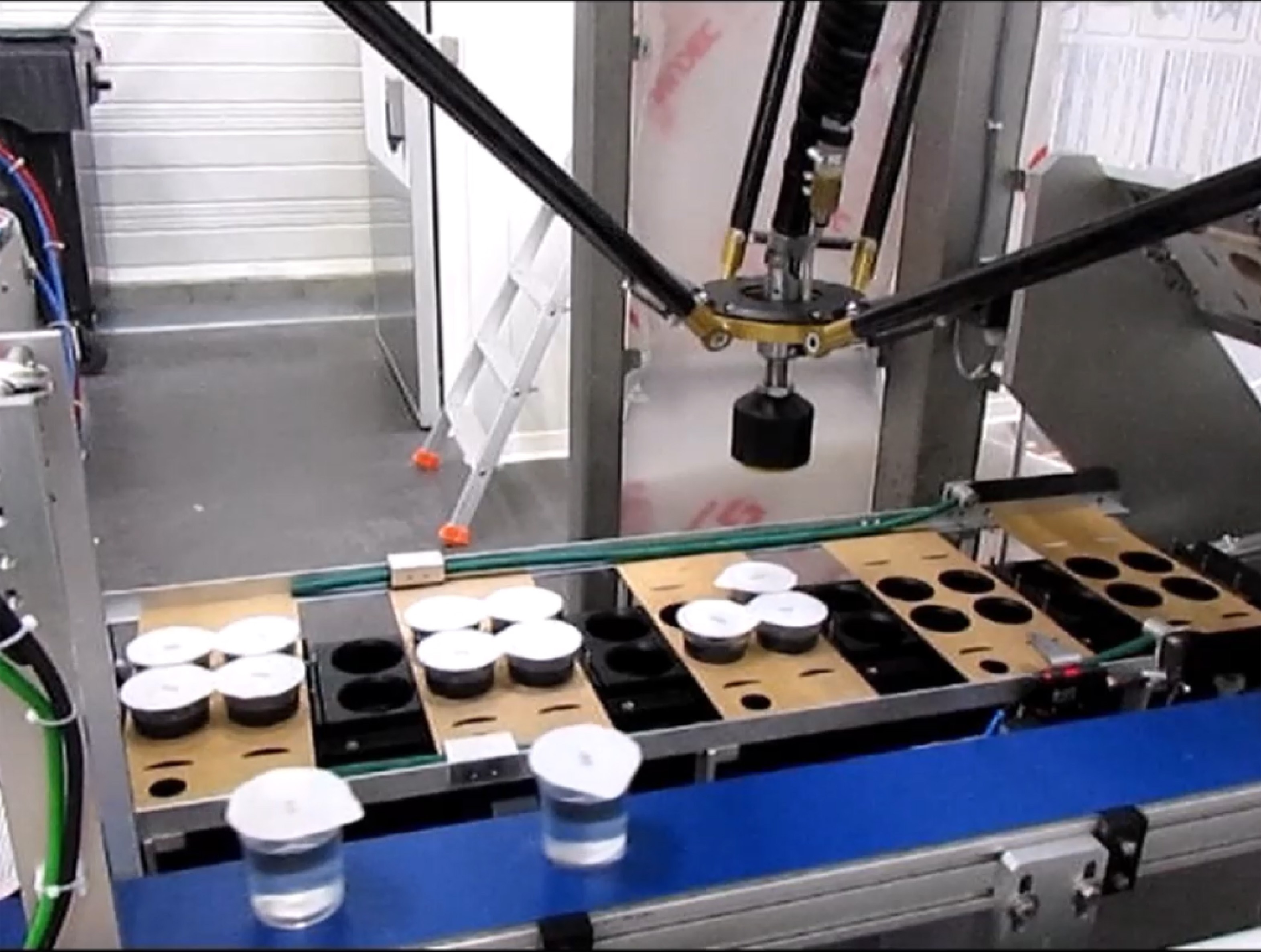

Our wrapping machines combine speed, precision, and adaptability to your dairy products. We guarantee multi-format handling with a machine that can handle single or batch products, such as yogurt packs that can consist of 2, 4, 6, or 8 products. Sleeve packing with an MG Tech machine allows for a high throughput adapted to your needs and helps you optimize your yield. Our vision and guidance systems ensure perfect product positioning for consistent sleeve packing throughout the entire production process.

Daory product case packing

Dairy product case packing is an important step, ensuring the preservation and protection of products throughout the entire logistics process following product packaging. Our multi-format case packers (top load or wrap) are designed to meet the standards of the supermarket and food service markets, ensuring secure packaging suitable for distribution. Case packing is an important packaging step in the agri-food sector, as it guarantees product quality until it is released for sale and allows for control, such as the assignment of batch numbers. It is also possible to integrate additional equipment such as smart conveyors with an integrated guidance system or sensors and cameras for product quality control.

Automated palletizing

Our automatic palletizers optimize your end-of-line operations, ensuring precise handling and increased pallet stability for transport and storage. There are several palletizing techniques for dairy products, such as layered palletizing with multiple cartons transported with each movement, cross-palletizing with alternating layers of products, and robotic palletizing, which places each carton in a specific location. Finally, for product stabilization and safety, our robotic palletizers can wrap and strap your pallets for smooth transport of your dairy products.

-

Our expertise in end of line packaging machines for dairy market

Packaging dairy products presents several challenges due to the fragility of the products, storage conditions, and various primary packaging formats. MG Tech is involved right from the secondary packaging stage, which plays a key role in logistics and product presentation during sales in supermarkets, for example. Secondary packaging can vary depending on the product and includes: crates, cardboard, sleeves, trays, packs, etc.

For cheese, whether packaged in cardboard or wooden boxes, our solutions allow the creation of trays and crates with ventilation holes, palletizing surfaces adapted to cooling, as well as flat or upright case packing for ready-to-sell products. For dairy products, our equipment, such as cartoners and triple-flap boxing machines, is designed to operate efficiently in cold environments, thus ensuring the quality and safety of your products. MG Tech is your strategic partner for optimizing your dairy packaging lines. Contact us for a personalized study of your industrial equipment needs.