Key Figure

Case speed

Speed/robot

Format change (assisted)

Format change (fully automatic)

Product features

- Case type: ECMA group A

- Closing type: hot melt glued or tuck-in flap closure

- Product type: trays, pots, sachets, bottles, tubes, cans, etc. …

-

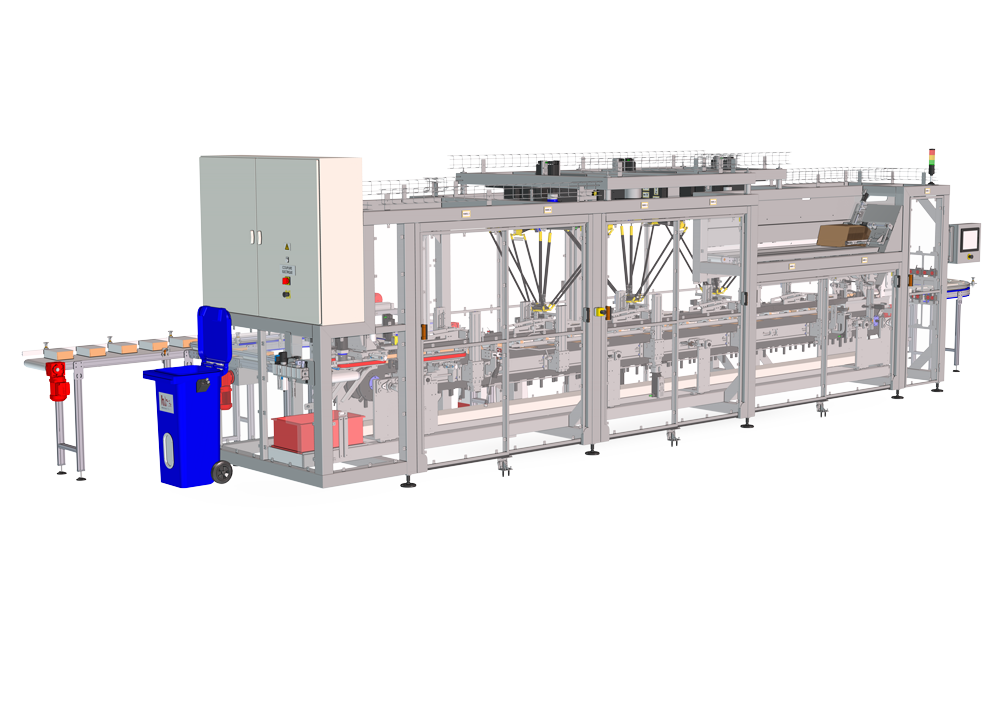

Technical features & benefits

#1 - High-Speed Operation

The MG Tech cartoning machine is engineered to handle high production demands, capable of processing a substantial number of cartons per minute. This high-speed capability ensures that production lines can maintain a fast pace, meeting the needs of industries requiring quick turnaround times.

The machine's design optimizes the speed without compromising the quality of carton formation or product placement, making it an ideal solution for large-scale packaging operations.

#2- Versatility

One of the key strengths of the MG Tech cartoning machine is its versatility. It can accommodate a diverse range of carton sizes and styles, such as tuck-in, glued, and auto-lock bottom cartons. This flexibility allows manufacturers to use the same machine for different products, reducing the need for multiple machines and streamlining the packaging process.

The machine's ability to handle various carton configurations makes it suitable for a wide array of industries, from food and beverages to pharmaceuticals and consumer goods.

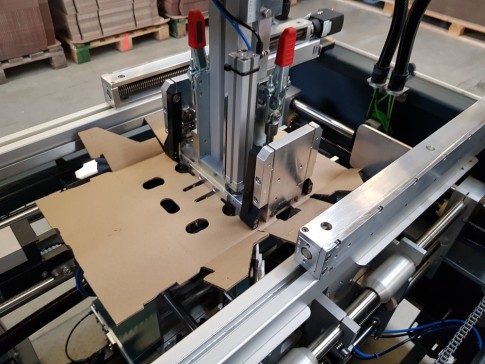

#3 - Automated Feeding System

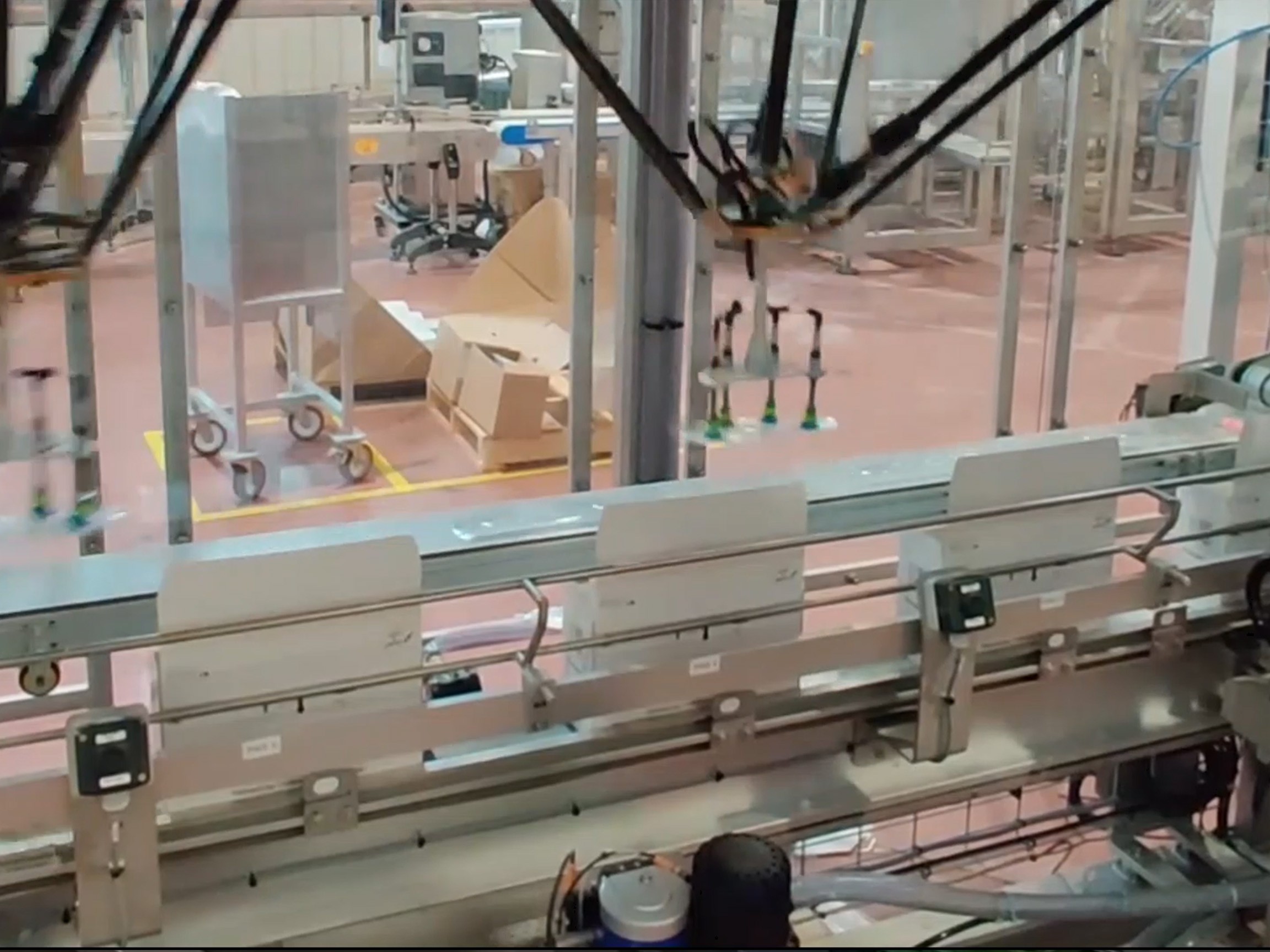

The automated feeding system is a critical component that enhances the efficiency and reliability of the MG Tech cartoning machine. This system automates key stages of the packaging process, including product feeding, carton erection, and product insertion into the cartons.

By reducing the need for manual intervention, the automated feeding system minimizes the risk of errors, ensures consistent quality, and increases the overall speed of the packaging line. Additionally, the system is equipped with sensors and precision positioning technology to guarantee accurate and reliable operations.

#4- Tool-Free Changeover

The MG Tech cartoning machine is designed with user convenience in mind, featuring a tool-free changeover system. This design allows operators to quickly and easily switch between different carton sizes and product types without the need for specialized tools.

The quick changeover capability significantly reduces downtime, enhancing productivity and efficiency. This feature is particularly beneficial for manufacturers who need to adapt their production lines frequently to accommodate different products or packaging requirements.

-

MG Tech expertise

Further information herePizza cartoning machines

Find out more about our pizza cartoning machines: a fully integrated solution ensuring box forming, pizzas filling into boxes and box closing. It provides a lot of different benefits such as: high production rate, ergonomic equipment, multiformat machine, flexible and quick format changeovers.

-

Do you need further information or a quotation?

-

Additional equipment of cartoning machine for a full end packaging line