-

Packaging Challenges Facing the Pharmaceutical and Cosmetic Industries

Pharmacy, parapharmaceutical, and cosmetic manufacturers face numerous challenges in meeting growing consumer demands. Rapid format changeover is the main challenge to avoid slowdowns and maintain optimal production.

#1 - PRODUCT SAFETY AND PROTECTION

- Protection against contamination: Packaging must ensure product integrity, particularly for medications and cosmetics sensitive to oxygen, humidity, or light.

- Ease of Traceability: The use of serialization and digital tracking (blockchain, RFID) helps track product progress through the supply chain.

#2 - SUSTAINABILITY AND ECO-RESPONSIBILITY

- Reduction of plastic packaging: Use of biodegradable, recyclable, or reusable materials.

- Weight and volume optimization: Reduction of secondary packaging to limit environmental impact and logistics costs.

- Innovative alternatives: Development of refillable packaging, bio-sourced materials, or vegetable-based inks.

#3 - TECHNOLOGICAL INNOVATION

- Smart packaging: Use of sensors or QR codes to provide interactive information on product usage or traceability.

- Precise dosing and optimal preservation: Airless bottles, precision droppers for cosmetic serums or liquid medications.

- Automation and personalization: Advanced printing technologies for personalized packaging and flexible production runs.

In summary, packaging in the pharmaceutical and cosmetic industries must combine safety, compliance, sustainability, innovation, and attractiveness to meet market expectations and regulatory requirements.

-

End-of-line packaging solutions for pharmaceutical products

We offer a complete range of packaging equipment, from case forming to palletizing.

The packaging process for pharmaceutical and cosmetic products is essential to ensure their integrity, traceability, and compliance with regulatory standards. In our workshops, we manufacture and test your machines under the best conditions to integrate them into your facilities and boost your production.

Our cartoning machines for the pharmaceutical and cosmetic industry

Certain pharmaceutical or cosmetic products must be protected by cardboard boxes or grouped into batches. We offer overwrapping machines and cartoning machines to handle your individual products and package them in boxes, adding additional elements such as leaflets, if necessary. Our high-speed machines are capable of handling a wide range of products and box sizes.

Our case erectors for the pharmaceutical and cosmetic industry

Our carton erectors are high-precision machines designed for rapid and automated packaging formation, ensuring optimal protection for sensitive products. They adapt to various production rates and offer great flexibility by allowing the configuration of various cardboard die-cut magazine formats to suit all your production needs.

Our multi-format case packers for the pharmaceutical and cosmetic industry

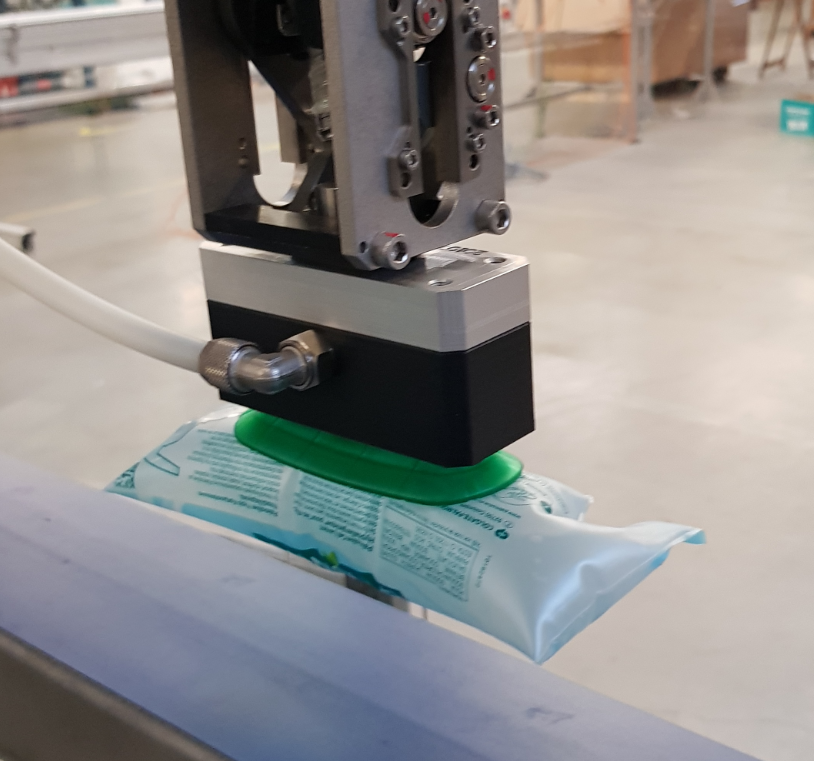

Case packing is a crucial step in product packaging, particularly for products with variable shapes such as bottles, tubes, or sachets. Our multi-format case packers are specifically designed to adapt to your product formats and incorporate user instructions, ensuring rapid processing and maximum productivity, while maintaining product quality. As the pharmaceutical sector is constantly evolving, our case packers allow for rapid format changes to accommodate new products.

Our robotic palletizers for the pharmaceutical and cosmetics industry

Finally, our automatic palletizers enable optimized logistics management by automating the assembly of boxes onto suitable pallets. Thanks to cutting-edge robotic technologies integrated into our robot and cobot palletizers, we guarantee optimal product security during transport, while improving the fluidity and traceability of the logistics flow.

-

Why Choose MG Tech for Packaging Your Pharmaceutical and Cosmetic Products?

MG Tech continually invests in research and development to offer ever-more efficient solutions for automating your end-of-line packaging solutions in the pharmaceutical and cosmetics sector.

We offer recognized expertise in the pharmaceutical sector with customized and adaptable solutions that enable our customers to ensure long-term production profitability. We address your production rate or format changeover issues with solutions approved by our customers. In addition, our teams support you throughout the project, and our responsive customer service ensures your machine ensures continuous production and benefits from preventive maintenance to avoid production downtime. Our goal is to help you optimize your packaging processes while ensuring the quality and compliance of your packaging.

By choosing MG Tech, you benefit from optimized management of production flows, a reduction in operational costs and increased traceability of your products, thus ensuring optimal security throughout the distribution process.