Key figures

Max production rate

Max palletization height

Footprint

Number of product arrival lines

Max pallet dimensions

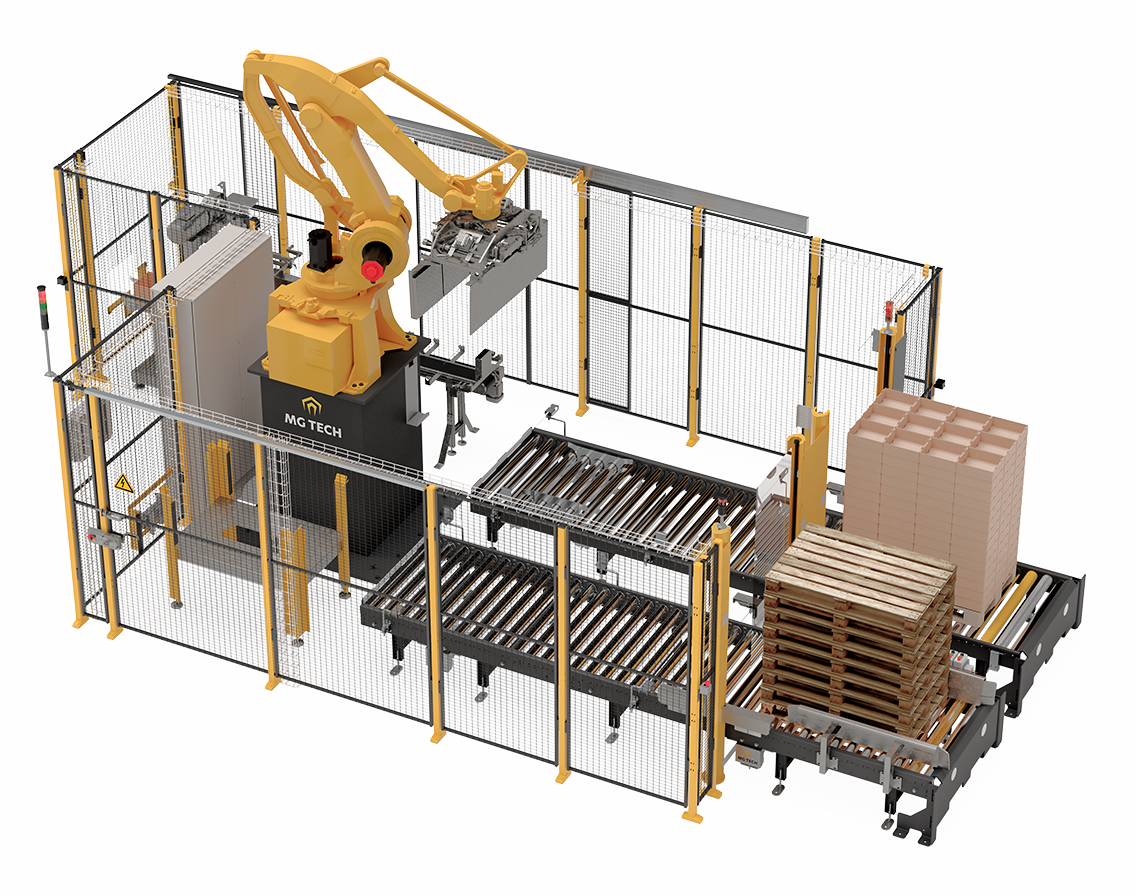

Machine features

- Type of palletization: columnar, crossed layers, with or without clearance, with cooling stack, with pallet overhang, etc.

- Type of gripper: by vacuum, by grippers or by shovel

- Package gripping: by unit, by row, by layer

- Pallet management: manual or automatic with conveyors and/or AGV mobile robots

-

Technical features and advantages

#1- Made in MG Tech

MG Tech designed and developed its PL-R100 robotic palletizer, selecting components from leading brands: Fanuc robots, Sick safety systems, Schneider PLCs, and more. Furthermore, all palletizing projects are managed by experts: project monitoring is handled by a dedicated and skilled team specializing in end-of-line packaging solutions, and equipment maintenance is provided by technical teams available throughout France.

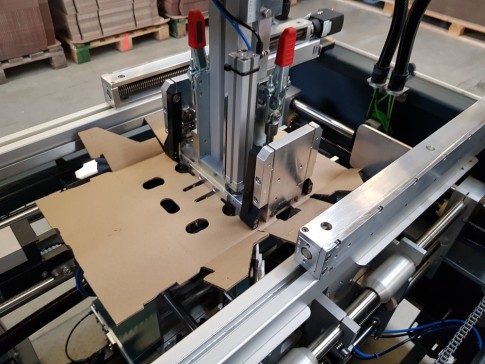

#2- Control of the three carton gripping methods

Our PL-R100palletizer is capable of gripping cases by vacuum, by gripper or by shovel. The control of these three methods allows MG Tech to offer the best technical solution based on the specific constraints of the cases.

The shovel gripping allows, in particular, to:

- ensure the products remain secure during transport, even the heaviest and most irregularly shaped items,

- control the correct engagement of stacking tabs in the case of columnar palletization.

#3- Design with automation, CPU and IHM

PL-R100palletizers are managed by a programmable logic controller (PLC) and an HMI (Human-Machine Interface) that provide direct access to the system's operation and product placement on the pallets. These systems also continuously inform the operating teams about the palletizer's operation and performance (production rate, output, service rate, etc.).

#4- Palletizing software available

PL-R100palletizers can be equipped with MG Tech palletizing software, which allows users to independently create new palletizing patterns (within the equipment's limitations), either from their 15" HMI display or from a PC application.

#5- Possibility of integrating complementary MG Tech equipment

In addition to palletizing, MG Tech offers pallet handling solutions using either traditional conveying systems (such as roller conveyors) or mobile robots (MG Tech offers combined AGV + palletizer solutions, which optimize factory layouts).

It is also possible to combine the palletizer with upstream automated case packing solutions. We offer wrap-around case packers (case packing from flat blanks) as well as top-load (products loaded from the top) and side-load (products loaded from the side) case packers.

The advantage of controlling all these functionalities allows us to offer complete end-of-line packaging solutions and provides manufacturers with a single point of contact for their entire project.

-

Do you need further information? Contact us now

-

Additional functions of palletization for a complete line