Key figures

Production rate

Footprint

Machine features

- Storage type: flat or upright

- Case types: 4 corners glued cases, shelf-ready trays, trays with ledge, stackable cases

- Product types: pots, pack, case, tri-fold boxes, bottle, thermoformed/sealed/filmed trays, sachet, flowpack/doypack, blisters…

-

Technical features & benefits

#1 – A multi-format machine suitable for a wide range of cases and products

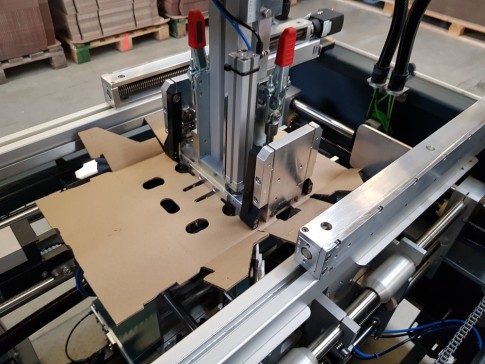

Our PM-TL100 top-load case packer is particularly well-suited for open cases (4 corners glued cases, trays with ledge, stackable cases) but also for shelf-ready trays with large windows and/or double walls (overhanging edges). Indeed, for perfect execution of this type of packaging, an independent MG Tech case erector upstream of the case packer is more appropriate because it ensures perfect case geometry during the stacking process and thus guarantees perfect production control.

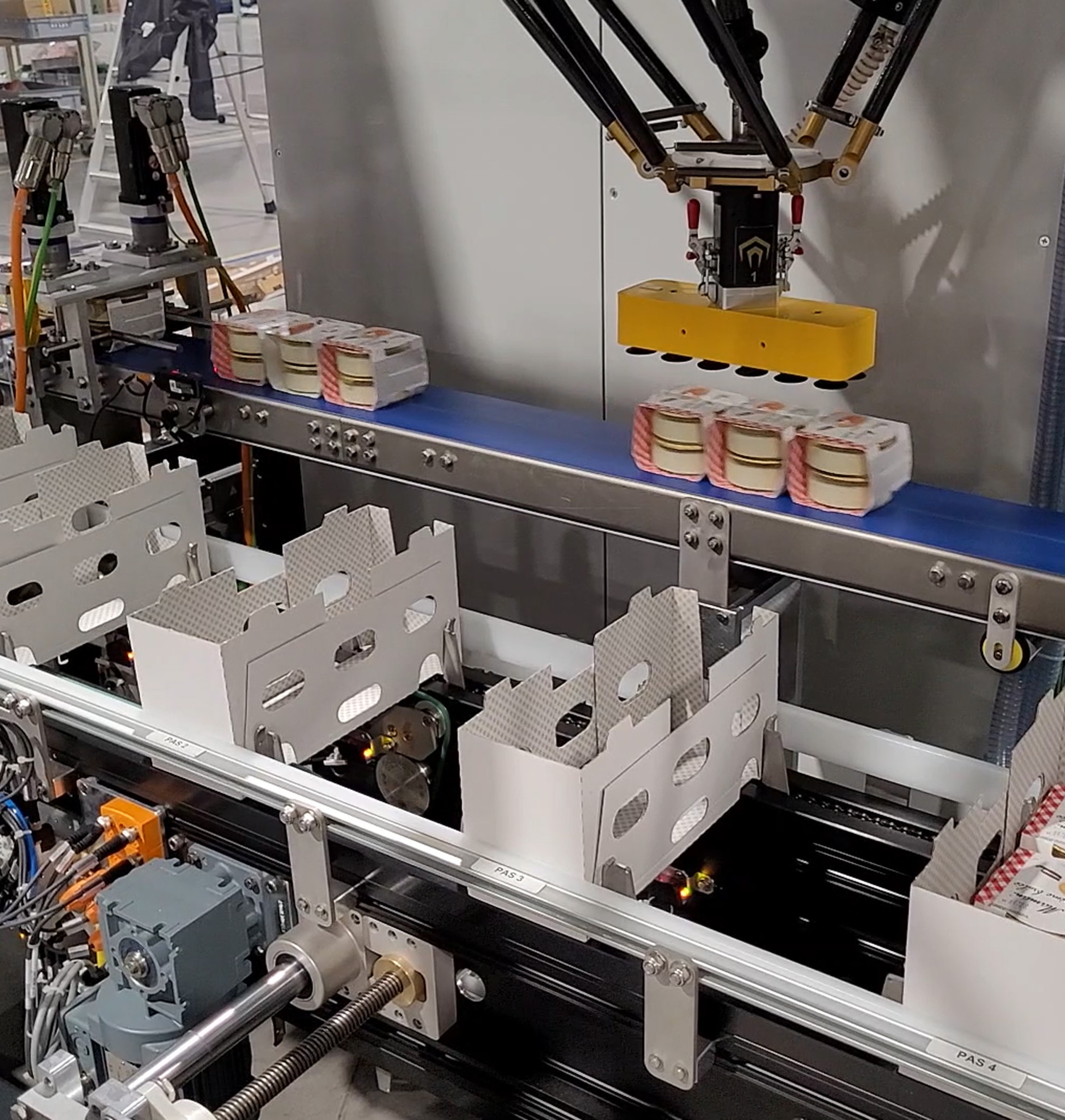

Our PM-TL100 top-load case packer can handle a wide variety of products, whether rigid (thermoformed trays) or more flexible (pouches). Product gripping for transfer into the cases is done using suction cups or grippers, gripping techniques which MG Tech is controlling. Using our own robots gives us complete control over product behavior during handling.

#2 – A simple and user-friendly case packer

The case packing process used in our PM-TL100 case packer is extremely simple. It faithfully replicates manual case packing, with the case being assembled beforehand, followed by the loading of the products using the gripper. The case packing function performed by our case packer is therefore very straightforward:

- Products circulate on a simple conveyor belt with detection for on-the-fly picking

- Case packing is performed by one of the robots in our range.

The simple design of the PM-TL100 case packer allows for the handling of multiple cases and products. A vision system (optional module) detects the arrival of products for tracking picking without any need for format changeovers. The robot then adapts to the production format and the desired storage type. Furthermore, case format changeovers can be done either manually or automatically using the side guides.

The modular design and the use of simple and perfectly mastered functions make the PM-TL100 top load case packer a very competitive solution for many automated case packing projects.

#3 - Equipment designed for easy cleaning

The PM-TL100 top-load case packer is designed for easy cleaning. Its simple design with minimal mechanical components is its greatest strength. Its construction, with all functions located at the top (vision system, robot, vacuum generator, etc.), ensures a clear area below the product and case conveying systems. All electrical wiring is also located at the top of the machine to prevent any areas where dirt can accumulate.

Its stainless-steel construction allows for easy cleaning of product and case circulation areas with water.

Furthermore, its large, full-height transparent doors provide complete visibility inside the machine and facilitate cleaning of the various areas.

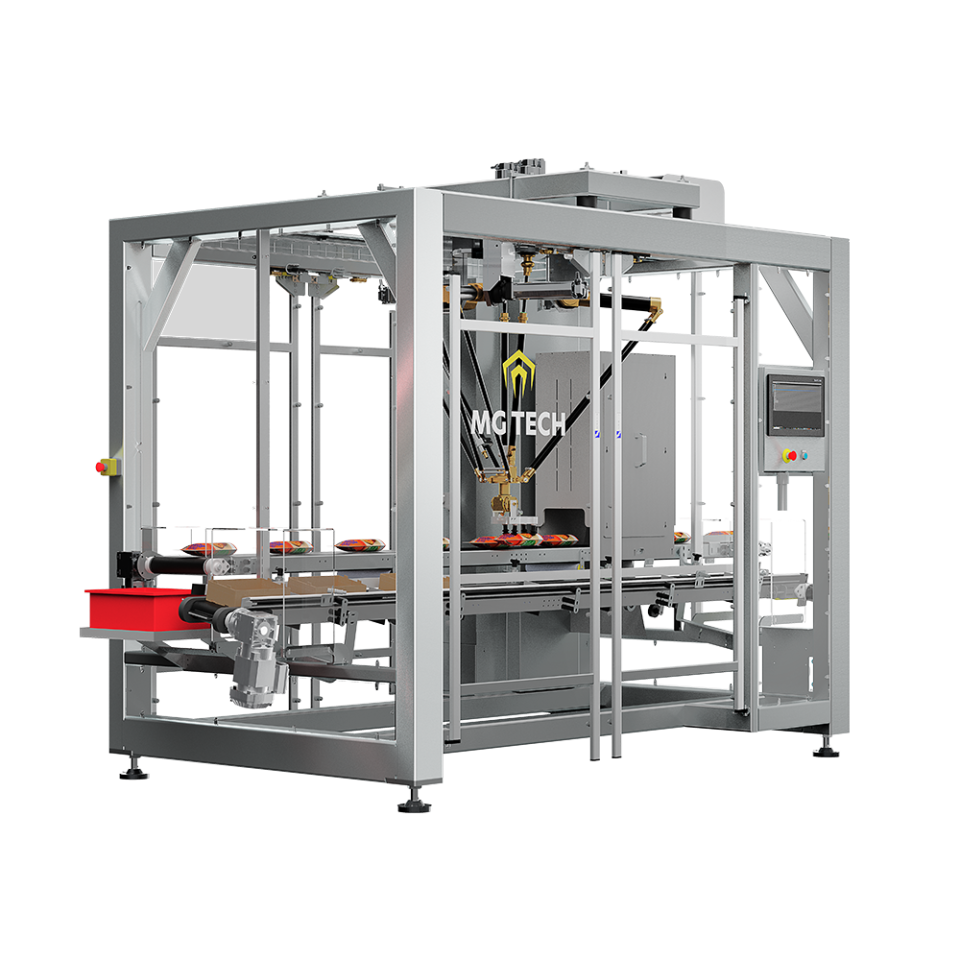

#4 – Compact footprint for seamless integration into the packaging line

Our PM-TL100 top-load case packer offers a compact solution. It can therefore be perfectly integrated into the ends of existing packaging lines. Separating the case packing from the case packing process allows for a much smaller machine (2.7 m x 1.7 m x 2.5 m high) and enables case stacking between the two functions, which generally results in improved performance. Case packing can be performed either directly upstream of the case packer (the machines can be connected via conveyor belts) or remotely in another area.

-

Do you need further information about our equipment? Contact us

-

Additional functions of top load packing for a complete line