Key figures

Maximum carried load weight

Maximum towed load weight

Maximum speed

Robot dimensions

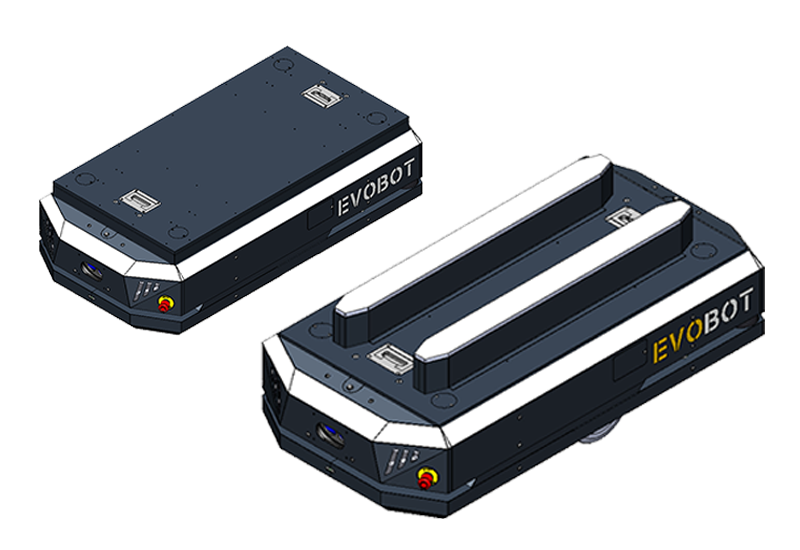

Product features

- Loading: automatic on feeding station

- Security: by front and rear scanner radars (360° vision)

-

A dedicated project management

MG Tech has the ability to immediately mobilize the human and technical resources necessary for the proper performance of your services. At each stage, a person is assigned to you for the successful completion of our service.

As soon as our current sales offer is signed, a robotic engineer will be assigned to you to orchestrate the smooth running of your service: from the finalization of the processes, through the mapping and the desired missions to the final acceptance.

He can be reached at any time. He is the guarantor of compliance with contractual commitments. He will provide you with an assistant and advisory role, will participate in periodic activity meetings and will ensure the smooth running of your project, both in terms of safety and that of deadlines and quality.

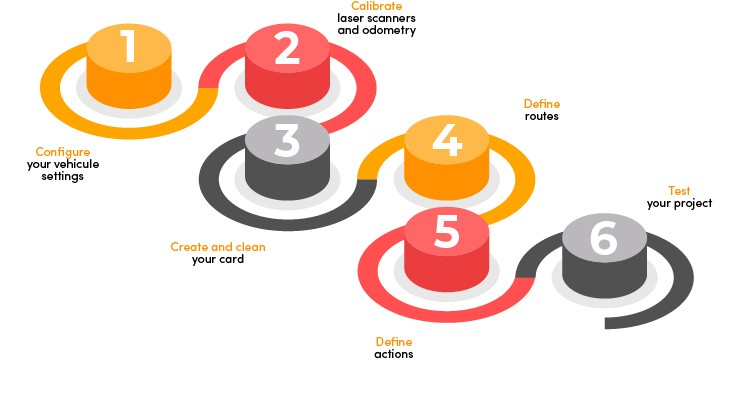

Our robotic engineers carry out the following missions in particular.

#2 - Sécurité avancée

Le robot mobile industriel AMR Evobot est équipé de capteurs et de caméras qui lui permettent de détecter les obstacles et d’interagir en toute sécurité avec son environnement, incluant les opérateurs humains. Cela réduit les risques d’accidents tout en maintenant une vitesse de déplacement efficace.

#3 - Amélioration de la productivité

Grâce à sa capacité à fonctionner 24/7 et à automatiser le transport interne de marchandises, le robot mobile industriel AMR Evobot permet de réduire les temps d'arrêt et d'augmenter la cadence des opérations. Il peut gérer des tâches répétitives et soulager les opérateurs de travaux à faible valeur ajoutée, permettant ainsi une optimisation des ressources humaines.

#4 - Facilité d’intégration

Le robot mobile industriel AMR Evobot est conçu pour s'intégrer facilement dans des systèmes existants. Il peut être programmé et configuré pour travailler avec différents équipements de production ou de manutention. Il s'adapte aux flux industriels sans nécessiter de réaménagement coûteux des installations.

#5 – Une gestion en mode projet

Dès la signature de notre offre commerciale actuelle, un ingénieur roboticien vous sera attribué pour orchestrer le bon déroulement de votre prestation : de la finalisation des process, en passant par la cartographie et les missions souhaitées jusqu’à la réception définitive.

Il est joignable à tout moment. Il est le garant du respect des engagements contractuels. Il vous assurera un rôle d’assistant et de conseil, participera aux réunions périodiques d’activité et s’assurera du bon déroulement de votre projet tant sur le point de la sécurité que celui du délai et de la qualité.

-

Besoin d'informations complémentaires ou d'un devis ?

-

Available configurations and functionalities

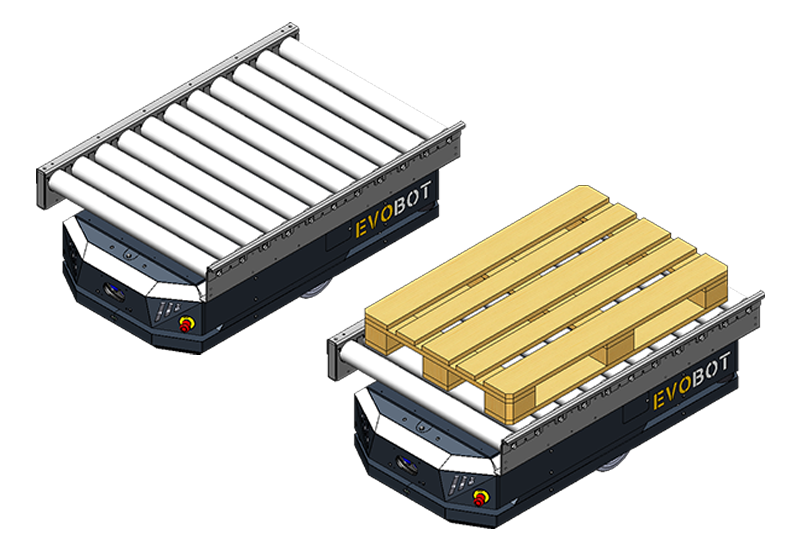

AMR robot with lifter

The Lifter is the complementary equipment of the Evobot AMR. It allows him to operate in turtle mode on his own. It allows to lift and move a load up to 1500 kgs. The dimensions of the Evobot make it possible to transport whole basic pallets (1200x800 mm or 1200x1000mm). For better hold of the pallets, it can be fitted with guide skis.

In situation, the AMR equipped with a lifter is generally associated with inert stations or of the U-shaped conveyor type to facilitate the pick-up and drop-off operations of the transported loads. The very low cost of these additional infrastructures ensures that the lifter has a very wide range of applications.

AMR robot with pallet conveyors

The Evobot has been designed to receive a pallet reception conveyor. This equipment ensures the transfer of pallets from existing conveyors to the AMR (and vice versa). Thus it requires very little adaptation of the automatic lines already in place.

In addition, it allows mixed operation: manual pick-up of pallets using a trolley or automatic management by AMR.

AMR robot with cobot or telescopic arm

The installation of a cobot (or a robot) on a mobile base transforms the AMR into a customized solution. This configuration is perfectly suited to small loads, single parts and especially multiple product references. Additional functions (control, positioning, etc.) can be performed by the on-board cobot.

It also exists with a telescopic arm, perfectly adapted to the management of bins with multiple entry and drop-off points. It requires very little development of the pick-up and drop-off stations because it is the equipment that ensures the transfer of the bins between the pick-up / drop-off station and the robot.

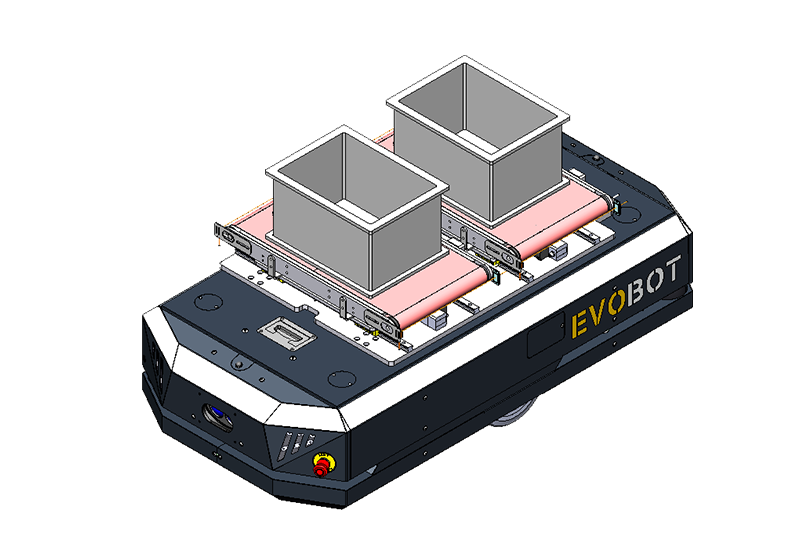

AMR robot with tray conveyors

The Evobot is designed to receive one or more tray reception and exit conveyors. In this configuration, the robot ensures the reception and distribution of these trays. This equipment can be associated with an elevator to thus have several heights of reception and exit of the trays.

-