-

Solutions tailored to the specific needs of industry

The MG Tech group designs machines that adapt to various industrial sectors, such as food, cosmetics, automotive, aeronautics, electronics, and luxury goods. The equipment is designed to ensure precise and secure product handling, while complying with current quality and safety standards.

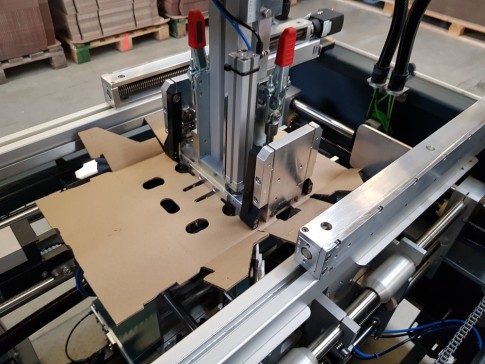

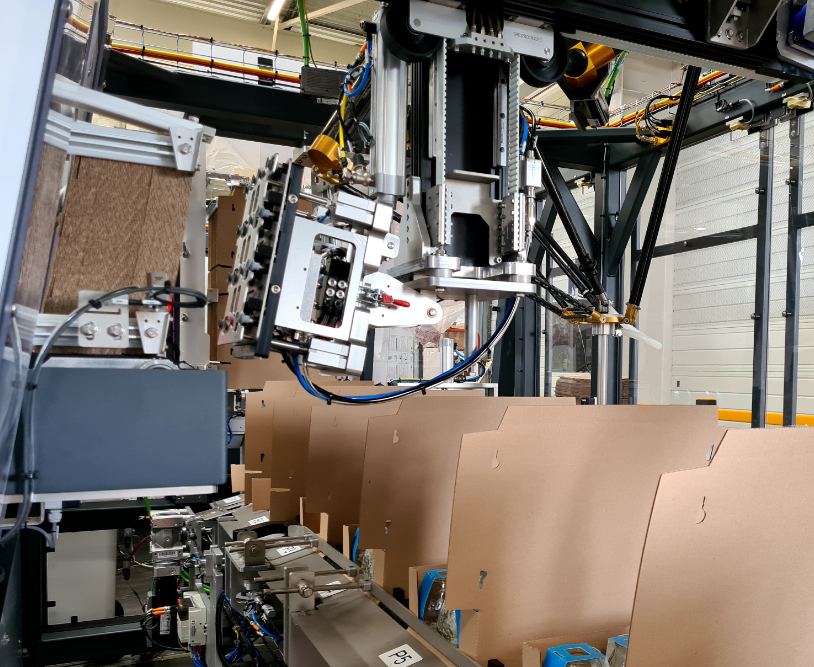

Automated Bulking and Case Packing

Our packaging solutions are designed to ensure optimal product protection and minimize waste. Our equipment accommodates all types of packaging, and our case erectors can produce multiple formats to ensure efficient production. Thanks to our knowledge of your market and your products, our teams develop solutions that take care of your products, with our robots programmed to handle even the most delicate items. Our range of case packers adapts to all types of products and allows products to be inserted into formed cartons.

Automated Palletizing

MG Tech palletizing systems efficiently manage pallet output at the end of the production line. Our palletizers allow you to optimize production flows and optimize pallet organization with higher throughput. MG Tech palletizers are designed to meet the need for flexibility in handling different carton sizes and pallet heights. Our systems easily adapt to a wide range of carton sizes, whether small or large, while also taking into account the variability of pallet heights according to the specific requirements of each production.

Transit, Control, and Traceability

We implement conveyor solutions to facilitate the labeling of your products and ensure their traceability throughout the supply chain. Thanks to labeling systems directly integrated into our conveyor systems, each product can be quickly labeled with specific information such as barcodes, batch numbers, manufacturing dates, or expiration dates, thus ensuring optimal tracking. In addition, our machine vision solutions allow for precise production monitoring of your batch-packed products, notably by verifying labeling quality, product compliance, and detecting any potential errors. This not only ensures product compliance, but also more efficient batch management. The information collected throughout the process can be integrated into a centralized management system, allowing for complete, real-time traceability. This way, your products can be sent to various locations with complete transparency, facilitating inventory management, compliance with standards, and optimizing logistics flows.

Intelligent Handling with AGV Mobile Robots

Automated guided vehicles (AGVs) and robotics play a crucial role in modernizing industrial processes. AGVs facilitate the autonomous transport of materials, parts, and products throughout the production line, reducing labor requirements and optimizing logistics flows. They navigate autonomously and improve efficiency by ensuring smooth and continuous inventory management while minimizing the risk of errors and accidents. At the same time, industrial robotics automates repetitive and complex tasks such as assembly, sorting, packaging, and palletizing. Robots, often combined with machine vision systems and artificial intelligence technologies, offer increased flexibility and precision. Integrating these technologies into the industrial sector increases productivity, reduces costs, and enables agile responses to market needs.

-

Personalized support for industry

MG Tech offers its clients comprehensive support, from project design to equipment commissioning, including team training and machine maintenance. We provide your teams with our expertise to ensure the success of your end-of-line packaging project. This approach ensures the smooth and efficient integration of packaging solutions into production lines.

Conclusion

The MG Tech group has extensive expertise in the field of end-of-line packaging machines for industry, with numerous success stories and clients reinvesting in new equipment to continue automating their production lines. Through its constant innovation, MG Tech helps companies optimize their production processes and strengthen their market competitiveness.