-

The challenges facing by industrial seafood manufacturers

In industrial seafood processing, end-of-line packaging equipment plays a key role in ensuring production efficiency and product traceability. High-performance equipment enables optimal production, ensuring the safety of your products from case packing to palletizing. The challenges are multiple: from technical aspects to the technology needed to handle various formats of packaged products, which can be fragile.

Compatibility with upstream machinery is important for easy integration of equipment into existing lines. We can integrate various equipment according to your end-of-line packaging needs in seafood processing.

Automating the end-of-line packaging in industrial seafood processing allows operators to benefit from improved working conditions, with our teams providing hands-on training on the machines.

-

Automate and optimize your end of seafood packaging line

We design and manufacture end-of-line packaging equipment adapted to the specific needs of the seafood processing industry. Our solutions can be customized to your products, whether fresh or frozen. We support you in achieving your goals: increasing productivity, ensuring traceability, and controlling your production. To achieve this, we install vision and camera controls to ensure optimal production.

To automate your end-of-line seafood processing, you can optimize several stages of your packaging line: from the carton erector to the palletization of your product-laden boxes.

Our case formers for seafood products

Our range of case formers adapts to your logistics flows with a variety of features. The flexibility of our case formers allows you to have a warehouse of varying sizes depending on the space in your production facility. Thanks to the flexibility of our case formers, we guarantee adaptability to your case formats to handle a variety of products (size, weight, packaging) and optimize the packaging of your seafood products.

Our automatic case packers and traceability for seafood products

From cartoning to case packing, our equipment is designed to support you throughout the entire end-of-line packaging process for your seafood products. Our cartoning machines accommodate all types of compact cardboard and can load products from above or flat, such as vacuum-cooked mussels or frozen fish.

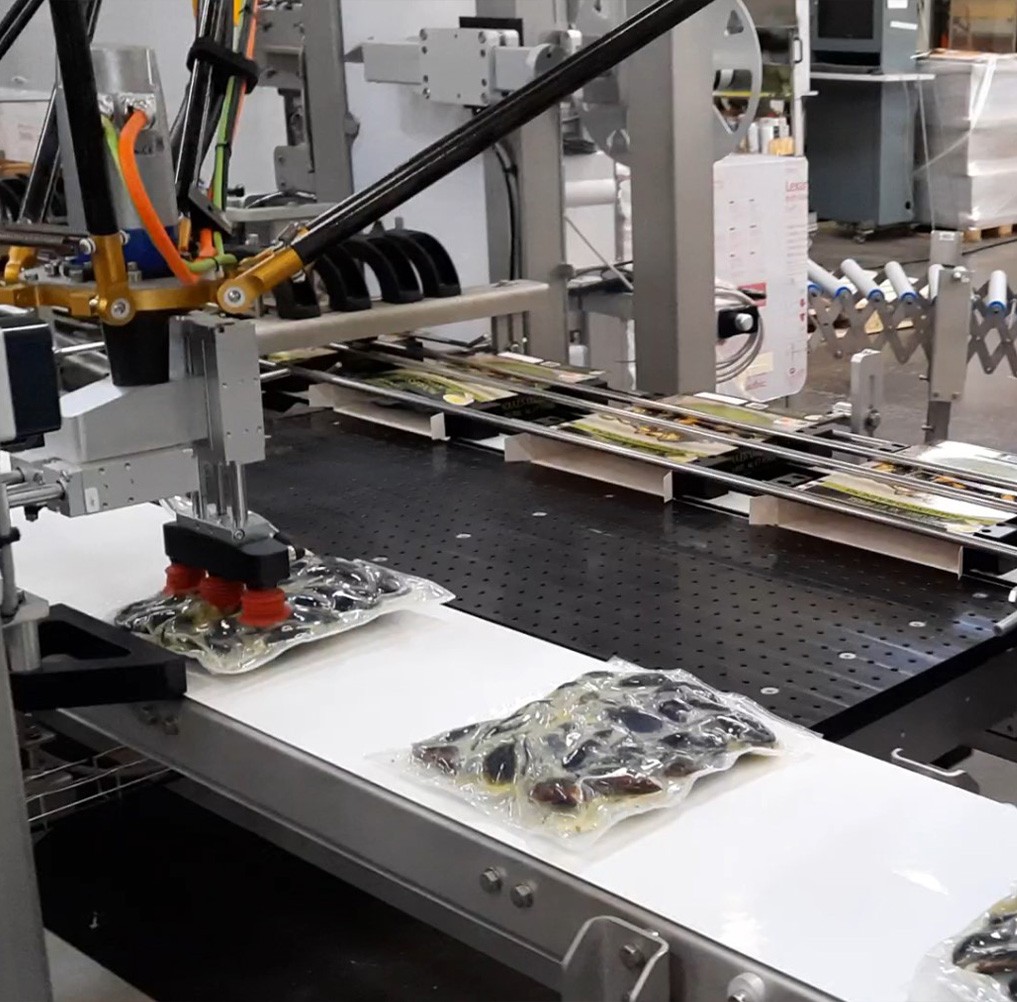

Our multi-format case packers automatically fill cases, trays, or cartons, whether for fresh, frozen, or vacuum-packed fish. Our Delta robots load cardboard boxes at high speeds to ensure production meets your objectives.

Case labeling is a key step in production monitoring and allows for the identification of product batches. Our machines are compatible with automatic labeling solutions, allowing the addition of logistics labels, barcodes, or traceability information to track your products in batches.

Our modular conveyors adapted to your end of packaging line

Packaged products are transferred using modular conveyors, meaning they adapt to your space and needs. The conveyors are easy to clean and resistant to various environments. They facilitate the connection between different end-of-line machines while maintaining a continuous flow. Our conveyor systems are suitable for transporting your packaged fish, crates, and cartons before and after loading, as well as for transporting your pallets.

Our robotic palletizing solutions for seafood products

Our robotic palletizers are designed to handle your various carton sizes. Thanks to flexible programming, they adapt to production rates and varying carton sizes and weights, while optimizing space and pallet stability. Our palletizing robots are adaptable to your space to optimize your end-of-line packaging.

-

Why choose MG Tech for your seafood packaging line?

- Agri-food expertise: Our machines are designed to meet the needs and various packaging applications of your seafood products, such as canned goods, vacuum-packed products, frozen products, etc.

- Safety: The design of our machines allows operators to work safely. All our machines are equipped with protective guards and emergency stop systems to prevent any risk of accidents during production, maintenance, or format changeover phases. Our machines also guarantee a high level of product safety thanks to vision systems that allow product inspection during the various packaging phases (welding inspection, best before date inspection, product presence inspection, etc.).

- Flexibility: We adapt each project to the specific constraints of your workshops and production area. Whether it's throughput or machine size, we offer custom-made machines that adapt to your products and your current and future needs.

- Customized support: From design to installation, including training your teams and maintaining your equipment... MG Tech teams support you every step of the way to ensure the success of your project. Our customer service team is there to answer your questions and help you get started with your new equipment. Do you want to upgrade your end-of-line packaging equipment in the seafood processing sector? Our teams support you in each new project.

-

Do you need a customized solution for your seafood packaging line?

Our expertise in end-of-line packaging in the food industry allows us to offer you customized solutions that take into account your constraints: space requirements, production rate, maintenance, etc. Contact our team for a personalized study and discover how our end-of-line equipment can improve your production performance.